Description

https://www.tianshangear.com/Metallurgical-Building-Materials-and-Mining-Gear.html

Tianshan is a top-tier building material gear manufacturer, specializes in producing advanced building material gear, cement mill gear, mining internal ring gear, and metallurgy double helical gear solutions. With our deep expertise, state-of-the-art technology, and commitment to quality, we deliver products that meet the rigorous demands of global industries, driving success in building materials, cement production, mining, and metallurgy sectors.

How Building Material Gears Boost Industrial Productivity

For industrial production in the building materials sector, durable and reliable gears are a fundamental necessity. Tianshan, as a trusted building material gear manufacturer, produces high-performance gears that excel in precision, longevity, and efficiency. Our building material gears are meticulously designed to handle heavy loads and high-speed operations while maintaining consistent performance. These gears are used in a wide variety of heavy-duty equipment, including rotary kilns, material crushers, conveyors, and mixers. Tianshan ensures the use of advanced materials, such as high-grade steel alloys, which are heat-treated and hardened to resist wear and deformation under extreme pressure. Each gear is precision-machined using advanced CNC technology to ensure smooth operation and perfect tooth alignment.

Additionally, Tianshan implements stringent quality control processes, including gear meshing simulations, torque load tests, and vibration analysis, to guarantee exceptional durability and optimal power transmission. By minimizing energy losses, wear, and maintenance requirements, Tianshan building material gears contribute to improved equipment efficiency, extended operating life, and lower operational costs, allowing manufacturers to maximize productivity and profitability.

The Role of Mining Internal Ring Gears in Heavy-Duty Mining Equipment

In the mining industry, mining internal ring gears are critical components that power the rotational movement of massive machinery such as crushers, excavators, and drilling rigs. These gears operate in harsh environments characterized by extreme loads, heavy shocks, dust, and abrasive materials, making durability and precision essential.

Tianshan mining internal ring gears are engineered to meet these rigorous requirements. Manufactured using premium-grade steel and subjected to advanced heat treatments, our gears achieve exceptional hardness, toughness, and resistance to wear. Precision machining ensures a perfect tooth profile, reducing friction and vibration, which in turn enhances the efficiency and lifespan of mining equipment.

To ensure top performance, Tianshan internal ring gears undergo rigorous quality checks, including gear contact analysis, load distribution tests, and fatigue life simulations. These processes guarantee that each gear delivers smooth and reliable power transmission under heavy-duty conditions. Mining operators benefit from reduced downtime, improved equipment efficiency, and lower maintenance costs, enabling them to achieve higher productivity and profitability in resource extraction processes.

Tianshan has established itself as a leader in producing mining gears that not only meet but exceed industry standards, making us a preferred supplier for global mining equipment manufacturers.

Why Are Cement Mill Gears the Backbone of Efficient Cement Production?

Cement production relies heavily on the performance and durability of its grinding equipment, particularly cement mill gears, which are vital for driving rotary kilns, crushers, and ball mills. Tianshan cement mill gears are designed to provide maximum power transmission efficiency, ensuring smooth and reliable operation in demanding conditions characterized by high torque and intense loads.

Our cement mill gears are crafted using cutting-edge manufacturing techniques, including precision forging, CNC milling, and advanced heat treatment processes. This results in gears with excellent surface hardness, tensile strength, and resistance to wear and fatigue. To meet the unique challenges of cement manufacturing, Tianshan's gears undergo rigorous testing, such as dynamic load analysis, thermal stress simulations, and durability testing under extreme conditions.

By offering reduced energy losses, exceptional alignment accuracy, and high-load tolerance, our cement mill gears help cement manufacturers maintain consistent production output while minimizing downtime. Tianshan's expertise ensures that our gears deliver unmatched performance, even under the harshest operating environments, making us a reliable partner for global cement producers seeking to optimize their operations and extend equipment life.

How Metallurgy Double Helical Gears Enhance Efficiency in Steel Production

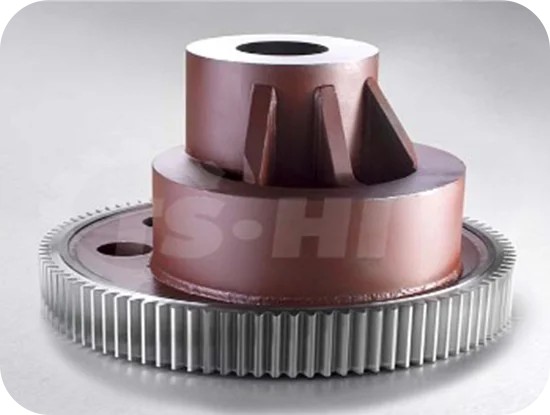

In steel and metallurgy production, metallurgy double helical gears play a crucial role in driving rolling mills, industrial presses, and other large-scale machinery. These gears are designed to handle immense loads, high torque, and continuous operation, ensuring stable and efficient performance under extreme working conditions.

Tianshan double helical gears are characterized by their unique design, featuring two helical teeth with opposing angles. This design eliminates axial thrust, reduces noise and vibration, and allows for smoother gear meshing. The result is a gear solution that improves efficiency, reduces energy consumption, and ensures longer operating life for metallurgy equipment.

Each double helical gear is meticulously manufactured using advanced CNC technology to achieve precise tooth geometry and alignment. High-quality steel alloys are heat-treated to enhance strength and resistance to fatigue and wear. Tianshan's gears are subjected to comprehensive testing, including alignment accuracy checks, load-bearing analysis, and thermal performance simulations, to ensure consistent, reliable operation.

By delivering superior power transmission and durability, Tianshan metallurgy double helical gears help steel manufacturers optimize their production lines, minimize downtime, and achieve higher productivity. Our gears are trusted by global metallurgical enterprises for their unmatched quality, precision, and long-term reliability.

Reviews

There are no reviews yet.